Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Cases

> Cases >

Adsorption and desorption

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

The company attaches great importance to environmental protection while vigorously improving the economic benefits of the enterprise and paying attention to product quality. The company's leaders, in line with the principle of creating a good production and living environment for the employees and the surrounding residents, collect and process the gas generated in the operation process and completely eliminate the hidden dangers of the enterprise's development. Entrusted by the company, shandong baolan environmental protection engineering co., ltd. for its preparation of waste gas treatment design. Based on the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we have compiled this scheme.

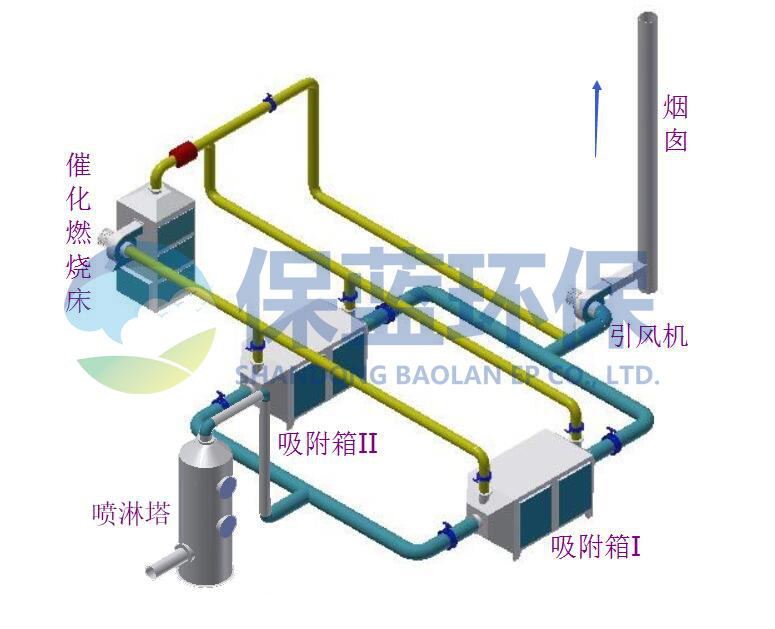

According to the operational cost and safety of the waste gas treated in this project, the process route of this project adopts "activated carbon adsorption desorption + safe catalytic combustion" as the core process to treat the waste gas of this project. The process route diagram of the project is shown as follows:

Process analysis:

(1) adsorption concentration -- desorption and desorption -- catalytic decomposition process. By 2 activated carbon adsorbers, 1 catalytic decomposer (auxiliary low pressure fan, valve, etc.). Exhaust gas after preprocessing to remove dust, granular material into activated carbon adsorber A and B, when activated carbon adsorber A close to saturation, will first deal with the gas automatically switch to the activated carbon adsorber B (activated carbon adsorber A stop operation), and then use thermal desorption of activated carbon adsorber A stripping, stripping off the organic matter from activated carbon. In the desorption process, the organic waste gas has been concentrated, the concentration is increased several times than the original, up to more than 2000ppm, the concentrated waste gas to the catalytic decomposition device, and finally become CO2 and H2O emission.

(2) after desorption and desorption, activated carbon adsorber A enters the waiting state, and when activated carbon adsorber B approaches saturation, the system will automatically switch back to the desorption and desorption of activated carbon adsorber B, so the cycle works.

(3) when the concentration of organic waste gas reaches above 2000ppm, the catalytic bed can maintain spontaneous combustion, without external heating. This scheme not only saves a lot of energy consumption, but also reduces the equipment investment because the catalytic decomposer only needs 1/5 (60000m3/h) of the original waste gas treatment capacity. This scheme is suitable for both continuous work and intermittent work.

(4) desorption and desorption of a single set of activated carbon adsorbent takes about 2-3 hours.

(5) the adsorption fan is controlled by a frequency converter, which can be adjusted according to the required air volume or the net negative pressure at the inlet of the device.

(1) adsorption concentration -- desorption and desorption -- catalytic decomposition process. By 2 activated carbon adsorbers, 1 catalytic decomposer (auxiliary low pressure fan, valve, etc.). Exhaust gas after preprocessing to remove dust, granular material into activated carbon adsorber A and B, when activated carbon adsorber A close to saturation, will first deal with the gas automatically switch to the activated carbon adsorber B (activated carbon adsorber A stop operation), and then use thermal desorption of activated carbon adsorber A stripping, stripping off the organic matter from activated carbon. In the desorption process, the organic waste gas has been concentrated, the concentration is increased several times than the original, up to more than 2000ppm, the concentrated waste gas to the catalytic decomposition device, and finally become CO2 and H2O emission.

(2) after desorption and desorption, activated carbon adsorber A enters the waiting state, and when activated carbon adsorber B approaches saturation, the system will automatically switch back to the desorption and desorption of activated carbon adsorber B, so the cycle works.

(3) when the concentration of organic waste gas reaches above 2000ppm, the catalytic bed can maintain spontaneous combustion, without external heating. This scheme not only saves a lot of energy consumption, but also reduces the equipment investment because the catalytic decomposer only needs 1/5 (60000m3/h) of the original waste gas treatment capacity. This scheme is suitable for both continuous work and intermittent work.

(4) desorption and desorption of a single set of activated carbon adsorbent takes about 2-3 hours.

(5) the adsorption fan is controlled by a frequency converter, which can be adjusted according to the required air volume or the net negative pressure at the inlet of the device.

CONTACT

BAOLAN EP INC.

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province