Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

DeNOx

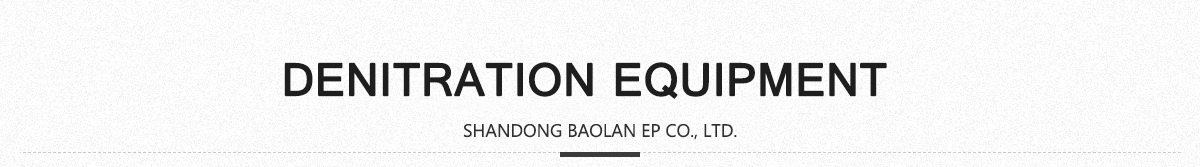

Selective Catalytic Reduction

SCR (Selective Catalytic Reduction) is a selective catalytic reduction technology. At present, ammonia catalytic reduction method is the most widely used technology. It has no by-products, no secondary pollution, simple device structure, high removal efficiency (up to 90%), reliable operation, and easy maintenance. Selectivity means that in the presence of oxygen and in the presence of oxygen, NH3 preferentially undergoes a reduction and removal reaction with NOx to form nitrogen and water, without oxidizing with the oxygen in the flue gas.

Its main reaction formula is:

(1) 4NO + 4NH3 + O2 → 4N2 + 6H2O

(2) 2NO2 + 4NH3 + O2 → 3N2 + 6H2O

In the absence of a catalyst, the above-mentioned chemical reaction is only carried out in a very narrow temperature range (about 980 ° C). When the catalyst is used, the reaction temperature can be controlled at 300-400 ° C, which is equivalent to the boiler economizer and air pre-conditioning. The temperature of the flue gas between the heaters is exothermic. Due to the low concentration of NOx in the flue gas, the increase in catalyst temperature caused by the reaction can be ignored.

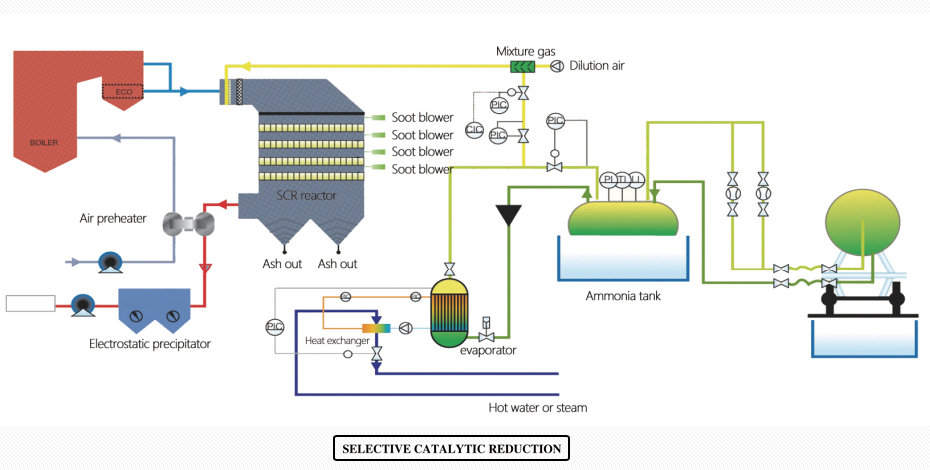

Selective Non-Catalytic Reduction

SNCR (Selective Non-Catalytic Reduction) is a selective non-catalytic reduction method. It is an economical and practical NOx removal technology. Its principle is based on NH3, urea [CO (NH2) 2], etc. Before the boiler is atomized or injected into the boiler, it is atomized by the heat in the furnace. Sprayed into the furnace temperature range of 800 ℃ ~ 1100 ℃, the reducing agent quickly thermally decomposed into NH3 and other by-products, and then NHCR and NOx in the flue gas undergo SNCR reaction to generate N2. It can therefore be considered a selective chemical process. The reducing agent has different reaction temperature ranges. This temperature range is called a temperature window, which has a great influence on the denitration efficiency of the method.

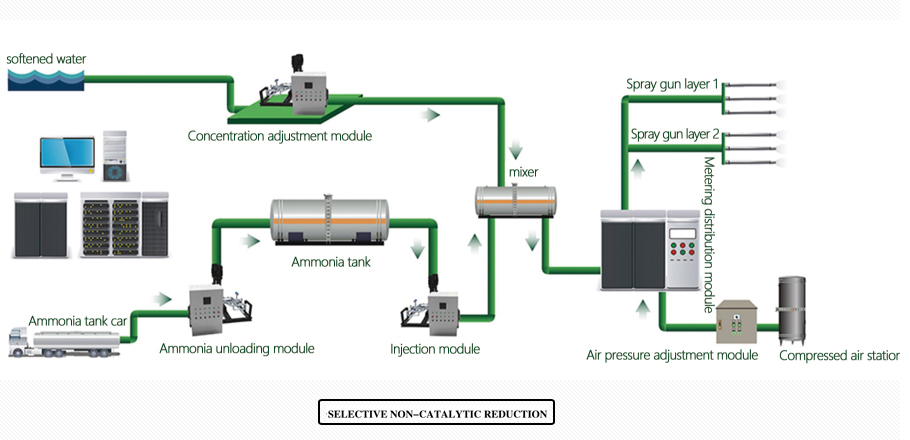

Denitration By Oxidation

Denitration By Oxidation mainly uses oxidants such as ozone, hydrogen peroxide or sodium hypochlorite to oxidize insoluble low-value nitrogen oxides to soluble high-value nitrogen oxides, and then absorb the nitrogen oxides with alkaline solution in the washing tower to reach Purpose of denitration. The denitration system can remove NOx, sulfur dioxide, and particulate matter in the flue gas at the same time under different concentrations and proportions of pollutants such as NOx, without affecting other pollutant control technologies. It is one of the traditional denitration technologies. Efficient complementary or alternative technologies.

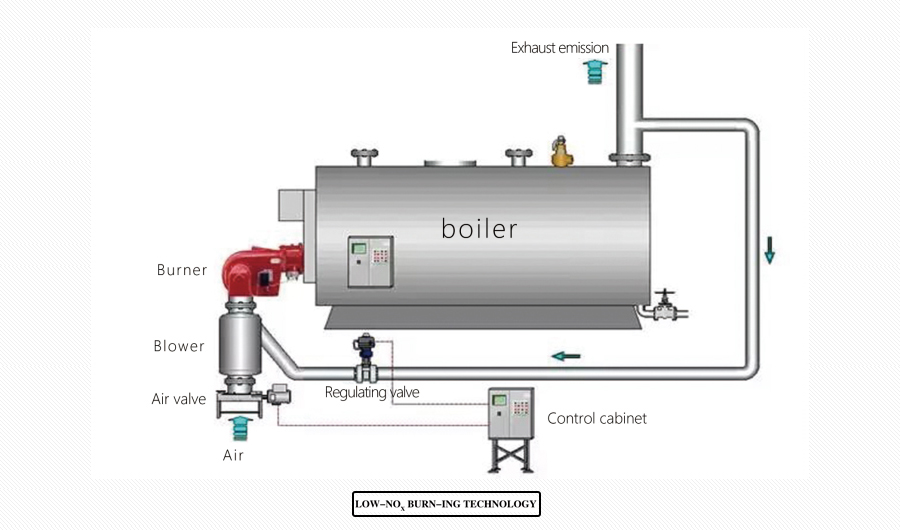

Low nitrogen oxide combustion technology is to improve the combustion equipment or control the combustion conditions, using a variety of combustion means in the furnace to control the production of NOx in the combustion process, in order to reduce the NOx in the tail gas of the combustion technology.

Service

● complete the project tasks according to the customer's requirements to ensure the project quality;

● the waste gas treatment device designed and provided by the company shall meet the local standards and national standards after treatment by the facility;

●guarantee the main equipment, provide technical services for the whole life, reply in time in case of any problems during the operation of the equipment, and arrange professional personnel to provide on-site services within 24 hours;

●when the warranty period expires, our company will only charge a certain cost for equipment maintenance and repair. Establish long-term contact and technical exchange with users, provide users with the latest technology and free technical consultation and service;

●during the commissioning of waste gas treatment system, and be responsible for training technical personnel. Including daily operation management, equipment operation procedures, common troubleshooting, regular maintenance of equipment, etc;

●regularly organize customer return visits, understand the system operation status, carefully handle customer feedback, and do a good job in engineering and technical consultation.

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province