Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Leather waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Leather waste gas source

The main source of waste gas in synthetic leather production is the volatilization of organic solvent:

(1) volatilization of resin and solvent during batching, transportation and storage;

(2) volatilization of organic matter during coating or soaking;

(3) volatilization of organic matter during heating in oven;

(4) volatilization of organic matter in the process of post-treatment.

Composition of leather waste gas

Waste gas pollutants are related to specific process and formula composition. For a certain process, the formula can often be changed, so the specific pollutants produced are not fixed. The common pollutants in the production process are:

① polyurethane dry process: organic solvent (DMF, toluene, xylene, butanone, etc.)

② polyurethane wet process: organic solvent (DMF)

③ PVC and other related processes: plasticizer smoke (dioctyl phthalate, etc.), vinyl chloride, hydrogen chloride, organic solvent, lead

④ post treatment process: organic solvent (DMF, toluene, xylene, butanone, butyl acetate, etc.), particulate matter

⑤ microfiber process: organic solvent (DMF, toluene, xylene, etc.)

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

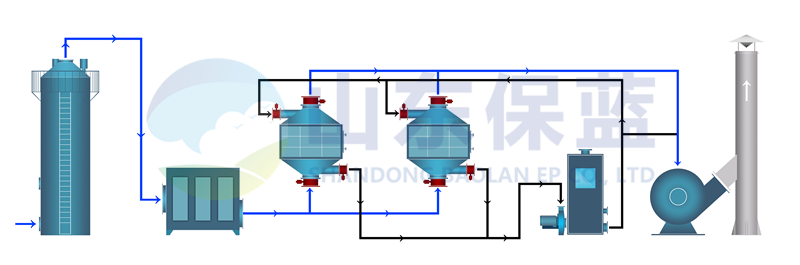

(1) there is a large amount of tar in the waste gas, so it is pretreated by the ionization trapper. The collected waste gas enters the ionization trapper. When the flue gas passes through, the dust and tar in the flue gas are ionized under the action of electric charge, moving towards the charged metal wire and pipe wall, and losing electric charge. Under the action of gravity, they fall to the bottom of the ionization trapper and flow out, so as to pollute The material can be degraded and removed;

(2) the captured waste gas enters the deodorization equipment. The ozone and · Oh (hydroxyl radical) produced by the reaction of high-energy photon beam with air decomposes and oxidizes the odor gas. At the same time, the chain structure of macromolecular gas is broken under the action of high-energy photon, which makes most of the organic gas materials transform into odorless small molecular compounds or completely mineralized;

(3) the treated waste gas enters into the deep purification system. When the activated carbon adsorber is close to saturation, the hot gas flow is used to desorb the activated carbon adsorber, and the organics are desorbed from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration has increased dozens of times than before, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally discharged as CO2 and H2O.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province