Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Cases

> Cases >

Cyclone dust collector

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

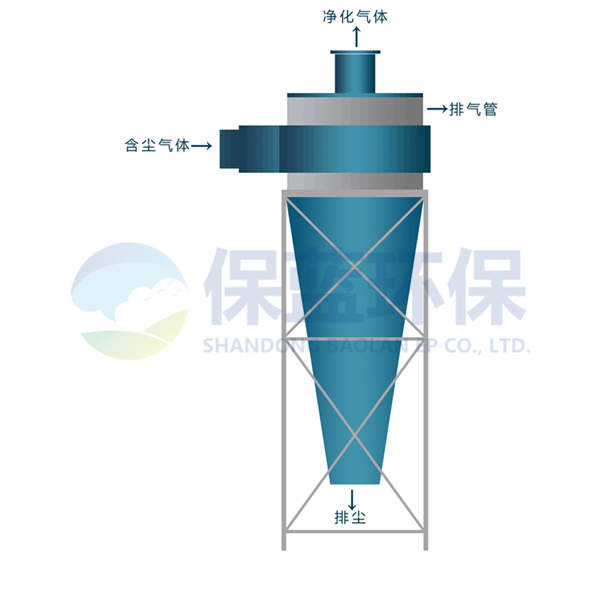

1. The structure of the cyclone dust collector is composed of an inlet, a cylinder, a cone, a exhaust pipe and a dust discharging device, as shown in the figure:

2. Working principle :

The working principle of the cyclone dust collector is shown in the animation f5-4-1. When the dust-containing airflow enters the dust collector through the tangent inlet, the airflow rotates in the dust collector, and the dust particles in the airflow move to the outer wall under the action of centrifugal force, reach the wall, and fall into the dust bucket along the wall under the action of airflow and gravity to achieve the purpose of separation.

The working principle of the cyclone dust collector is shown in the animation f5-4-1. When the dust-containing airflow enters the dust collector through the tangent inlet, the airflow rotates in the dust collector, and the dust particles in the airflow move to the outer wall under the action of centrifugal force, reach the wall, and fall into the dust bucket along the wall under the action of airflow and gravity to achieve the purpose of separation.

3. Analysis of flow field in cyclone dust collector:

(1) composition of flow fieldExternal vortex - a flow of air that rotates downward along the outer wall.Internal vortex - airflow that rotates upward along an axis.Eddies - eddies formed by the interaction of axial and radial velocities.Including the upper eddies -- the top cover of the cyclone dust collector, the local eddies formed between the outside of the exhaust pipe and the inner wall of the cylinder, which can reduce the dust removal efficiency;Lower eddies - local eddies that form in the vertical direction of the collector, in the outer layer and at the bottom.

(2) movement of airflow and dust particles in the cyclone dust collectorThe dust-bearing airflow enters the dust collector by the tangent inlet and rotates in a spiral shape along the outer wall from top to bottom. The downward-rotating airflow is called the external vortex. The outer vortex reaches the base of the cone, turns upward, rotates upward along the axis, and finally exits through the discharge tube. This upward-rotating airflow is known as an internal vortex. The downward outer vortex and the upward inner vortex rotate in the same direction. When the airflow rotates, the dust particles are driven by inertial centrifugal force and move outward to the wall. The dust particles that reach the outer wall fall into the dust bucket along the wall under the combined action of airflow and gravity.When the airflow rotates downward from the top of the dust collector at a high speed, the pressure at the top will drop, and part of the airflow will rotate upward along the outer wall with fine dust particles. After reaching the top, the airflow will rotate downward along the outer wall of the discharge pipe and discharge from the discharge pipe. This rotating flow is known as a supereddy. If a certain distance is maintained between the inlet of the dust collector and the top cover, no interference from the inlet airflow, the upper vortex is more obvious.The measurement of the airflow movement in the cyclone dust collector shows that the actual airflow movement is very complicated. In addition to tangential and axial motion there is radial motion. In the measurement, t. linden found that the radial velocity of the outer vortex was centripetal, while the radial velocity of the inner vortex was outward, and the velocity distribution was symmetrical.

(3) tangential velocityTangential velocity is the main component of velocity and the main factor of centrifugal force.The variation law of tangential velocity is as follows:

(1) composition of flow fieldExternal vortex - a flow of air that rotates downward along the outer wall.Internal vortex - airflow that rotates upward along an axis.Eddies - eddies formed by the interaction of axial and radial velocities.Including the upper eddies -- the top cover of the cyclone dust collector, the local eddies formed between the outside of the exhaust pipe and the inner wall of the cylinder, which can reduce the dust removal efficiency;Lower eddies - local eddies that form in the vertical direction of the collector, in the outer layer and at the bottom.

(2) movement of airflow and dust particles in the cyclone dust collectorThe dust-bearing airflow enters the dust collector by the tangent inlet and rotates in a spiral shape along the outer wall from top to bottom. The downward-rotating airflow is called the external vortex. The outer vortex reaches the base of the cone, turns upward, rotates upward along the axis, and finally exits through the discharge tube. This upward-rotating airflow is known as an internal vortex. The downward outer vortex and the upward inner vortex rotate in the same direction. When the airflow rotates, the dust particles are driven by inertial centrifugal force and move outward to the wall. The dust particles that reach the outer wall fall into the dust bucket along the wall under the combined action of airflow and gravity.When the airflow rotates downward from the top of the dust collector at a high speed, the pressure at the top will drop, and part of the airflow will rotate upward along the outer wall with fine dust particles. After reaching the top, the airflow will rotate downward along the outer wall of the discharge pipe and discharge from the discharge pipe. This rotating flow is known as a supereddy. If a certain distance is maintained between the inlet of the dust collector and the top cover, no interference from the inlet airflow, the upper vortex is more obvious.The measurement of the airflow movement in the cyclone dust collector shows that the actual airflow movement is very complicated. In addition to tangential and axial motion there is radial motion. In the measurement, t. linden found that the radial velocity of the outer vortex was centripetal, while the radial velocity of the inner vortex was outward, and the velocity distribution was symmetrical.

(3) tangential velocityTangential velocity is the main component of velocity and the main factor of centrifugal force.The variation law of tangential velocity is as follows:

Outer vortex area: r↑, tangential speed ut↓;

Inner vortex region: r↑, tangential velocity ut↑.

Inner vortex region: r↑, tangential velocity ut↑.

CONTACT

BAOLAN EP INC.

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province