Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Pesticide waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Source and harm of pesticide waste gas

(1) source of pesticide waste gas

① feeding port of reaction kettle. As the synthesis reaction of pesticides is exothermic reaction, the odor produced in the reaction process is emitted through the feeding door, and the odor is very strong.

② reactor outlet and closed centrifuge solvent outlet.

③ the products that have been preliminarily desolvated shall be dried in an open drying pond or in a drying room. Although the concentration of malodorous substance emitted by the product in the drying process is relatively low, the total amount of malodorous substance emitted is large due to the large spread of the original medicine, and the influence on the surrounding environment is large due to the small diffusion and dilution capacity of the ground.

(2) hazards of pesticide waste gas

Pesticide waste gas is harmful to human body in many aspects, among which the common organic waste gas in industrial waste gas is harmful to human body mainly as follows: benzene organic matter damages human central nervous system and causes nervous system obstacle. When the concentration of benzene vapor is too high (the content in the air is up to 2%), it can cause fatal acute poisoning. PAHs have strong carcinogenicity. Benzoic acid organic compounds can make cell proteins deform or coagulate, which leads to systemic poisoning.

Composition of pesticide waste gas

(1) the main components of the waste gas pollution in the production workshop of the pesticide plant are toluene, dicyanophenol, methanol, phosgene and hydrogen chloride;

(2) in the process of pesticide production, sulfur-containing organic compounds (mainly mercaptan and thioether) will be formed, which have pungent odor, most of them are unorganized emissions, without treatment, causing serious pollution to the surrounding environment.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

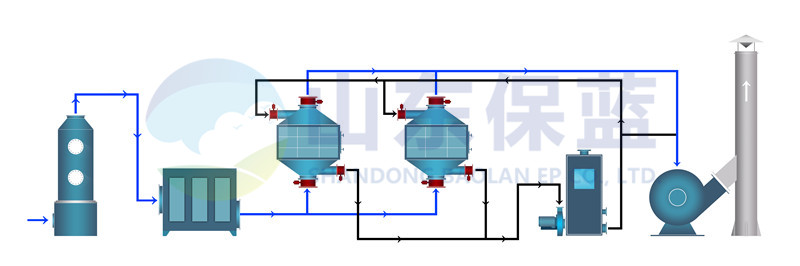

(1) after the dust and granular substances are removed by pretreatment, the waste gas is sent to the activated carbon adsorber I and II. When the activated carbon adsorber I is close to saturation, the treatment gas is automatically switched to the activated carbon adsorber II (the adsorption operation of the activated carbon adsorber I stops), and then the activated carbon adsorber I is desorbed and desorbed with hot gas flow to desorb the organic matters from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration has increased dozens of times than before, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally discharged as CO2 and H2O.

(2) after the desorption, the activated carbon adsorber I will enter the standby state. When the activated carbon adsorber II is close to saturation, the system will switch back automatically, and at the same time, the activated carbon adsorber II will be desorbed and desorbed, so it will work in cycle.

(3) when the concentration of organic waste gas reaches more than 2000 ppm, the catalytic bed can maintain spontaneous combustion without external heating. The scheme not only greatly saves energy consumption, but also reduces equipment investment because the treatment capacity of catalytic decomposer only needs 1 / 5 of the original waste gas treatment capacity (60000m3 / h). This scheme is not only suitable for continuous work, but also suitable for intermittent work.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province