Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Pharmaceutical waste gas treat

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Source and harm of pharmaceutical waste gas

(1) source of pharmaceutical waste gas

In the production process, pharmaceutical enterprises will use some organic solvents with low melting point and good volatility. This kind of solvent is likely to volatilize with the production process and lead to pollution. Its discharge mainly occurs in the operation units such as feeding, reaction, solvent recovery, filtration, centrifugation, drying, discharging, etc.

(2) hazards of pharmaceutical waste gas

A large number of organic solvents (such as DMF, benzene series, organic amine, ethyl acetate, dichloromethane, acetone, methanol, ethanol, butanone, ether, dichloroethane, acetic acid, chloroform, etc.) are used in the medical and chemical industry to volatilize and form a gas with irritating odor and odor, which is toxic to some extent. Long term emission will inevitably worsen the regional atmospheric environment quality and affect the lives of nearby residents The body is harmful. Therefore, effective control of VOCs Pollution in pharmaceutical industry has become an important problem to be solved.

Composition and characteristics of pharmaceutical waste gas

(1) pharmaceutical waste gas composition

DMF, benzene series, organic amine, ethyl acetate, dichloromethane, acetone, methanol, ethanol, butanone, ether, dichloroethane, acetic acid, chloroform, etc.

(2) characteristics of pharmaceutical waste gas

1) there are many discharge points, large amount of discharge and serious unorganized discharge. The yield of pharmaceutical and chemical products is low, the solvent consumption is large, the solvent waste gas emission points are many, and the solvent waste gas is mostly low-level and unorganized emission, and the solvent waste gas concentration is high.

2) intermittent emission. The reaction process is basically intermittent, and the solvent waste gas is also discharged intermittently.

3) unstable emission. The composition of solvent waste gas is complex, and the types and concentrations of pollutants vary greatly. The same unit may discharge pollutants of different properties in different periods.

4) solvent waste gas has a wide range of influence. VOCs in solvent waste gas mostly have odor properties, low odor region value, easy to diffuse and wide range of influence.

5) there are many accidents such as "running, falling, dripping and leaking". Because there are many flammable and explosive substances in the production process, the reaction process is intense, and the risk of production accidents is large.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

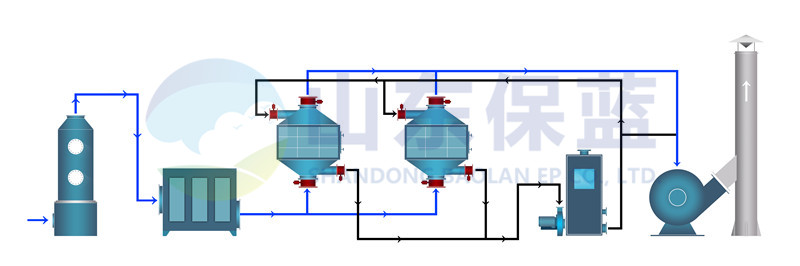

(1) after the dust and granular substances are removed by pretreatment, the waste gas is sent to the activated carbon adsorber I and II. When the activated carbon adsorber I is close to saturation, the treatment gas is automatically switched to the activated carbon adsorber II (the adsorption operation of the activated carbon adsorber I stops), and then the activated carbon adsorber I is desorbed and desorbed with hot gas flow to desorb the organic matters from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration has increased dozens of times than before, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally discharged as CO2 and H2O.

(2) after the desorption, the activated carbon adsorber I will enter the standby state. When the activated carbon adsorber II is close to saturation, the system will switch back automatically, and at the same time, the activated carbon adsorber II will be desorbed and desorbed, so it will work in cycle.

(3) when the concentration of organic waste gas reaches more than 2000 ppm, the catalytic bed can maintain spontaneous combustion without external heating. The scheme not only greatly saves energy consumption, but also reduces equipment investment because the treatment capacity of catalytic decomposer only needs 1 / 5 of the original waste gas treatment capacity (60000m3 / h). This scheme is not only suitable for continuous work, but also suitable for intermittent work.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province