Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Boiler waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Boiler exhaust gas composition

Boiler flue gas mainly contains dust, sulfur dioxide, fluoride, etc.

(1) sulfur dioxide and hydrogen sulfide are harmful to life. Sulfur dioxide is 2.26 times heavier than air. It is a colorless and smelly gas with suffocation. After long-term exposure to SO2 with a concentration of 5.23 ± 0.52mg/m3, the human body will suffer from bronchopneumonia like, liver cell turbid swelling and keratopathy.

(2) fluoride refers to organic or inorganic compounds containing negative fluorine. Like other halogens, fluorine forms a single negative anion (f −). Fluorine can form binary compounds with all elements except he, NE and ar. From the deadly toxin sarin to the drug favelon, from the refractory calcium fluoride to the highly reactive sulfur tetrafluoride belong to the category of fluoride.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

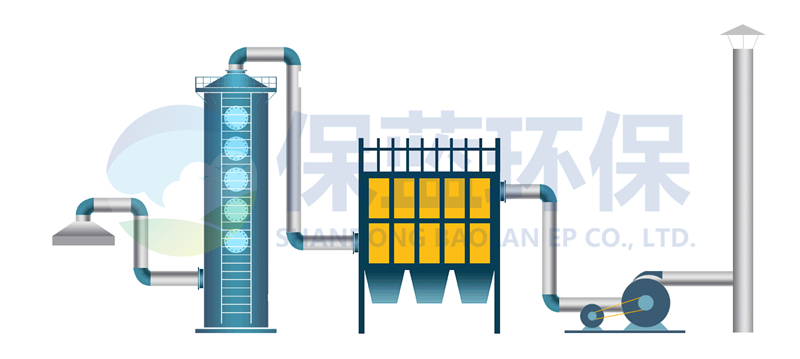

(1) the flue gas contains dust, fluoride and sulfur dioxide, and the flue gas enters the desulfurization tower. The double alkali flue gas desulfurization technology uses sodium hydroxide or sodium carbonate solution as the starting desulfurizer, and the prepared sodium hydroxide or sodium carbonate solution is directly sent into the desulfurization tower to wash and remove the SO2 in the flue gas, so as to achieve the goal of flue gas desulfurization, and then the desulfurization product is regenerated into sulphurous acid through the desulfurizer regeneration pool The sodium or sodium hydroxide shall be recycled in the desulfurization tower. Fluoride in flue gas dissolves in water to form hydrofluoric acid and water. Hydrofluoric acid and calcium hydroxide react to form calcium fluoride precipitation and water.

(2) when the flue gas passes through the desulfurization tower, the spray system can catch the dust particles in the flue gas at the same time. The uncapped dust enters the wet electrostatic equipment. The principle of the wet electrostatic precipitator is that tens of thousands of volts DC high voltage is applied between the anode and the cathode line. Under the action of strong electric field, corona layer is generated around the corona line, and the air in the corona layer is subject to avalanche ionization, resulting in a large number of The process is called corona discharge. The dust (FOG) particles that enter the wet electrostatic precipitator along with the flue gas collide with the positive and negative ions and are charged. The charged dust (FOG) particles move to the anode due to the Coulomb force of the high-voltage electrostatic field. When they arrive at the anode, they release the charge, and the dust (FOG) particles are charged by the anode The collected dust forms a water film, which flows upward to the lower liquid tank or absorption tower by gravity or flushing, and is separated from the flue gas. After reaching the standard, the flue gas will be discharged through the chimney of fan pipe.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province